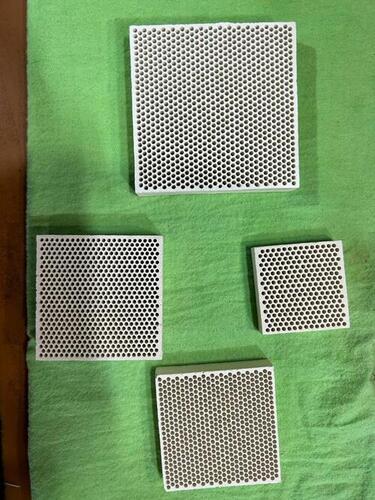

foundry ceramic filter

Product Details:

- Color white

- Usage foundry

- Product Type ceramic filter

- Height customize Inch (in)

- Length customize Inch (in)

- Size customize

- Material aluminum

- Click to View more

foundry ceramic filter Price And Quantity

- 32 INR/Piece

- 2000 Piece

foundry ceramic filter Product Specifications

- white

- ceramic filter

- foundry

- customize Inch (in)

- foundry

- customize Inch (in)

- customize

- New

- aluminum

foundry ceramic filter Trade Information

- mundra

- Cash Advance (CA) Cash in Advance (CID) Cheque

- 2000 Piece Per Week

- 7 Days

- Yes

- Free samples are available

- Central America Asia Australia North America South America Western Europe Middle East Eastern Europe Africa

- Himachal Pradesh Andaman and Nicobar Islands Uttarakhand Daman and Diu Dadra and Nagar Haveli Lakshadweep South India East India Assam Arunachal Pradesh Bihar Chandigarh Delhi Gujarat Goa Haryana Jammu and Kashmir Madhya Pradesh Maharashtra Mizoram Meghalaya Manipur Punjab Pondicherry Rajasthan Sikkim Tamil Nadu Telangana Tripura West Bengal Nagaland Uttar Pradesh Karnataka North India Andhra Pradesh Kerala Central India Odisha Jharkhand West India Chhattisgarh All India

- ISO 9001:2015 WHO_GMP ENVIROMENT 14001:2015

Product Description

A ceramic foundry filter is a type of filter used in the casting process of metals. It is typically made of porous ceramic material and is designed to remove impurities and contaminants from molten metal before it is poured into a mold.

During the casting process, the metal is heated to a high temperature and poured into a mold to create the desired shape. However, the metal can contain impurities such as slag, sand, or other particles that can affect the quality of the final product. Ceramic foundry filters help to remove these impurities by allowing the molten metal to pass through the porous ceramic material, which traps the contaminants and allows only the clean metal to pass through.

Ceramic foundry filters come in a variety of shapes and sizes, depending on the specific needs of the casting process. They can be used with a range of metals, including steel, iron, and aluminum, and are designed to withstand the high temperatures and pressures of the casting process.

Overall, ceramic foundry filters play a crucial role in ensuring the quality and consistency of cast metal products by removing impurities and contaminants from the molten metal.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS